SunForce™ is a highly functional material with unprecedented design possibilities.

How Thin Can It Be Molded?

The ability to design components of industrial products with thin walls contributes to savings in space, weight, and cost, and as such brings major advantages. Generally, however, molded foam products are manufactured by using air to fill a mold with large-diameter foam beads, and this method is therefore often unsuitable for molding of thin-wall products.

Thin-Wall Applications With SunForce™

SunForce™ beads are manufactured in a fine granule size (approximately 1 mm) to ensure that wall thicknesses as thin as possible can be designed in foam material. As a result, thin-wall molding difficult with conventional foams is now possible, and with increased freedom in product design.

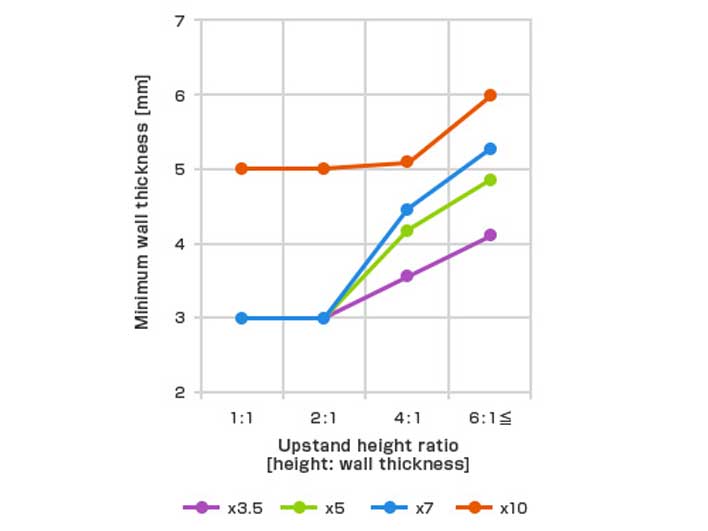

Thin-Wall Molding with SunForce™

Although the recommended wall thickness of SunForce™ depends on the shape of the molded product and conditions of use, in terms of the bead filling property and molded product strength, it is recommended that thickness is 4 mm or more for SunForce x7 products. Furthermore, while this restriction does not apply to lower-end x5 beads and minute molded shapes, since UL registration is certified as flame-retardant V-0 at 3 mm thickness or more, in terms of flame retardancy, a thickness of 3 mm or greater is required even for the thinnest parts (5 mm or greater for x10)

Application Areas

SunForce™ BE - Automotive Application

Automotive industry (exterior and interior parts, structural battery parts)

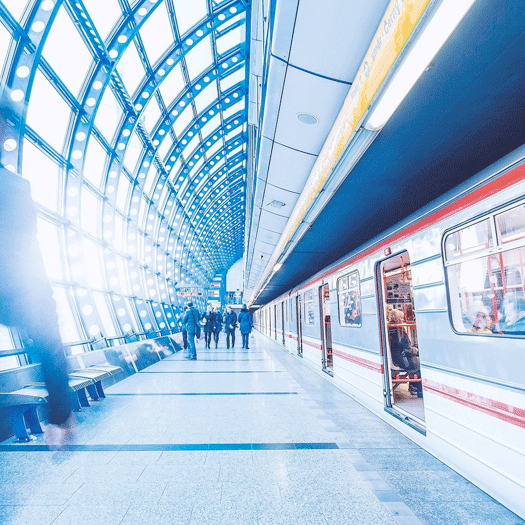

Public transportation

(airplane components, train components, railway infrastructure, electrical parts, seat parts)

Other industries

Other industries (E-wave applications)