Motor vehicles · Batteries

(Heat insulation, Weight saving)

The automotive industry is facing serious challenges, as requirements regarding safety and CO2 emissions are getting increasingly tighter. Lithium-ion batteries are an essential component for the electrification of vehicles. As lithium-ion batteries show their full performance only at a stable temperature, both heating and cooling units are installed to the automotive battery pack, especially for PHEVs (plug-in hybrid electric vehicles) and BEVs (battery electric vehicle). However, creating the right temperature environment for the battery consumes a significant amount of energy, so an optimized thermal management of battery packs will become increasingly important. At the same time, safety issues such as fire protection and crash behavior stand on top position at the OEMs’ agenda.

Asahi Kasei has developed SunForce™ – a particle foam based on the engineering plastic m-PPE (modified polyphenylene ether) – as a solution to these challenges. Compared to standard foams made of polystyrene or polyolefin, the use of m-PPE equips this foamed material with unique properties, opening new doors for applications in thermal management and fire protection.

Requirements Of Automotive Industry

Flame Retardancy

The current common standard for flame retardant materials used in the internal compartments of motor vehicles is FMVSS 302 (Federal Motor Vehicle Safety Standard). FMVSS 302 tests horizontal burning speed of materials. However, the requirements for flame retardancy in some parts of hybrid cars and electric cars are stricter. Materials used in these parts are required to be in compliance with UL-94 V-1/V-0 (more stringent ratings than FMVSS 302). SunForce™, which is developed based on FMVSS 302 standards, is also UL-94 V-0 certified.

Heat Resistance And Rigidity

Motor vehicles are designed to withstand harsh environments.

The materials used in the engine compartment have to be able to endure high temperature up to 120 degree Celsius. Even with insulation from the air in the compartment, materials still have to withstand heat of about 80 to 100 degree Celsius. SunForce™ can be used in the engine compartment as it is able to withstand 100 degree Celsius without compromising its functionality.

Heat Insulation

Lithium-ion battery and electronic components such as microcomputers and controllers in modern vehicles require a constant temperature for optimized performance. Water condensation from cooling of these components can cause problem to the electronics. To maintain optimal temperature of car interiors, measures such as installation of thermal insulation materials and utilization of A/C air are applied. SunForce™ can maintain a proper temperature for these components by insulating heat inside and from the outside.

For Usage Around Lithium-Ion Batteries

As heat is generated during the charging of battery, cooling of the cells becomes necessary before the temperature exceeds the heat resistant temperature of the cells.

On the other hand, heating is required to ensure power generation from the battery is maximized at places with low temperature. This requires very sophisticated uniform temperature management for battery system which has many cells.

In recent years, the capacity (number of cells) of lithium-ion batteries used in vehicles has increased and these batteries cannot depend on natural heat dissipation that is possible in small battery units.

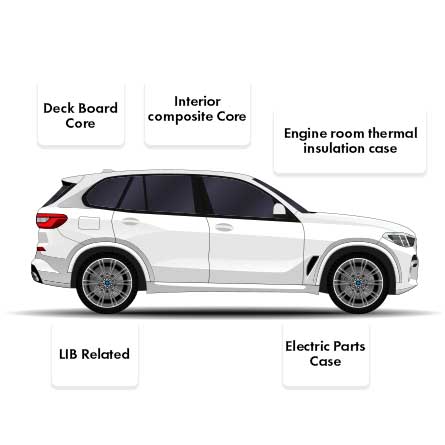

By using SunForce™ inside the automotive battery case, we can

- Control of air flow from the conditioning system

- Insulate heat from the outside

- Hold cells, cables and fans in place

A low-cost weight-saving example is a SunForce™ battery case which covers and holds battery cells and cables in position. Utilizing the design versatility of SunForce™, an air-duct to enable cool A/C air into the case is built into the structure.

Temperatures Around Lithium-Ion Batteries

Cooling At High Temperature

By utilizing SunForce™ design like that shown below, cool air from the conditioning system can be guided into the battery and cells can be cooled evenly. Heat transfer can even be facilitated by using SunForce™ composite (with metal mesh) at the bottom of the cells. As the case is thermally insulated from open air, less cooling energy is needed, and condensation is prevented.

Heating At Low Temperature

It is well-known that battery system cannot work effectively under excessively low temperature. To avoid this issue, some EVs or high performance HVs have special built-in heaters to manage the temperatures of their battery cells. As SunForce™ keeps the heat inside of the battery unit of electric and hybrid cars, we can prevent heat loss from the battery after the car has stopped. Starting up becomes easier as the battery now requires lesser heating and time to generate high output of power.

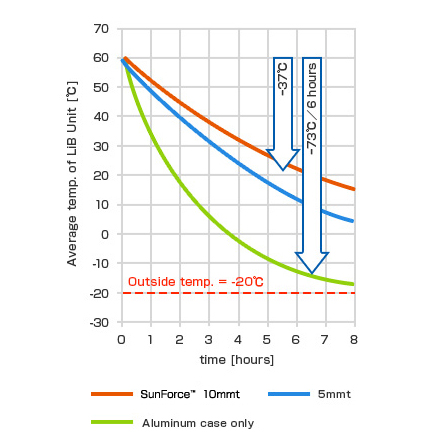

Comparing the time of reduction in battery temperature using SunForce™

Thermal barrier effect of SunForce™

We studied the heat loss effect in lithium-ion battery when SunForce™ is used on the inner side of the aluminum case of the battery.

- Outside air temp.: -20℃, Start air temp. inside unit: 60℃

- SunForce™ specification: [Expansion ratio] 7 times, [Thickness] 10mm and 5mm

- Outer panels: Aluminum 2mm

For Usage As Interior Core Material

Many automotive interior applications require heat resistance of more than 80℃ and high-temperature material structure rigidity. SunForce™ can be used in areas like pillars (where airbags, electronic components are installed), deck board etc. Compared to conventional EPP (expanded polypropylene) foam, SunForce™ is able to withstand higher temperatures, has higher precision in shape and is flame retardant.

As a core material for pillars, SunForce™ can be shaped and structured to hold airbags and electronics components, leading to parts and weight reductions.

As Core Material For Deck Boards

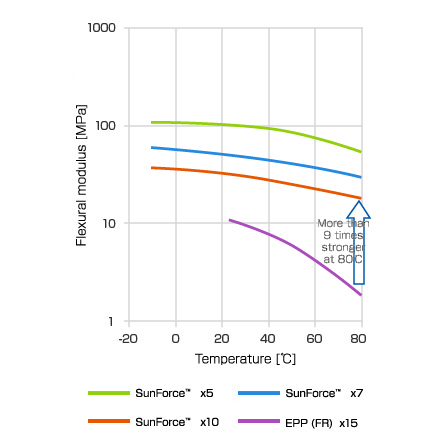

Deck boards require lightweight and high flexural modulus simultaneously.

Deck boards are usually made of metal reinforced injection blow molded plastic or a combination of expanded foam material with sheets with high strength.

Conventional foamed plastics cannot fulfill the requirements for heat-resistance and flame retardancy.

Unlike these materials, SunForce™ is able to:

- Reduce weight by more than 20%

- Expand free space (using a sleek design)

- Withhold rigidity at high temperature

- Provide safety (as it is flame retardant)