SunForce™ is a highly functional material with unprecedented design possibilities.

Discover our lightweight material SunForce™

Foam is a material characterized by an internal bubble structure. The large number of bubbles ensures that it is very light in comparison with the original material. Polystyrene foams and foamed polyolefins made from general purpose plastics are foamed plastics in general use, however SunForce is a highly functional foamed engineering plastic manufactured from modified polyphenylene ether plastic (m-PPE).

How light is SunForce™

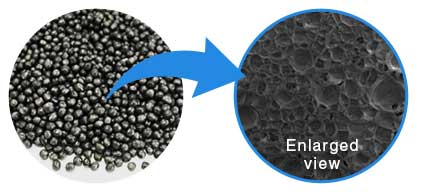

SunForce is foamed by injecting an inorganic gas into mini pellets developed exclusively for foaming, and is manufactured and sold as foamed beads already foamed as granules.

The foaming ratio and density of the foam are determined by the expanded volume, assuming that the material (solid) before foaming has a foaming ratio of “x1.”

SunForce comes in a range of foaming beads with foaming ratios of x3.5, x5, x7, and x10. When foamed, weight per volume is small, ensuring a lightweight product.

At low foaming ratios (x3.5) strength and thin-walled molding are the predominant characteristics, while at high foaming ratios (x10), advantages of thermal insulation and cost come to the fore. Please select the foaming ratio according to the conditions of use and characteristics required.

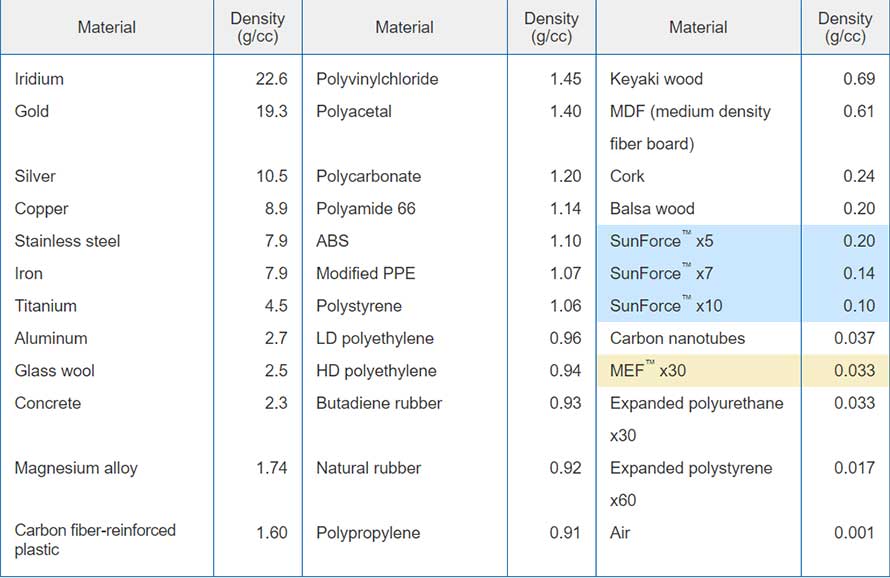

Compare the density of SunForce ™

with the following materials

As is apparent, density is very low compared to materials such as metal and injection plastics, and the use of SunForce when designing components contributes greatly to reduced weight of the final product. Reduced weight leads to many benefits such as easier portability of products, reduced load during product assembly, and improved fuel efficiency.

As a simple example, a comparison of 10cm square boxes constructed in aluminum, plastic, and SunForce shows the latter to be 40% to 50% lighter (assuming similar strength). See below.

Aluminium: 0.7mm thick

ABS Plastic: 2mm thick

SunForce x7: 8mm thick

Application Areas

SunForce™ BE - Automotive Application

Automotive industry (exterior and interior parts, structural battery parts)

Public transportation

(airplane components, train components, railway infrastructure, electrical parts, seat parts)

Other industries

Other industries (E-wave applications)